Initial status of central filter tank before oil skimmer installation 最初的狀況

Initial status with thick tramp oil and mud damaged pump system seriously. 高濃度廢油有損泵浦

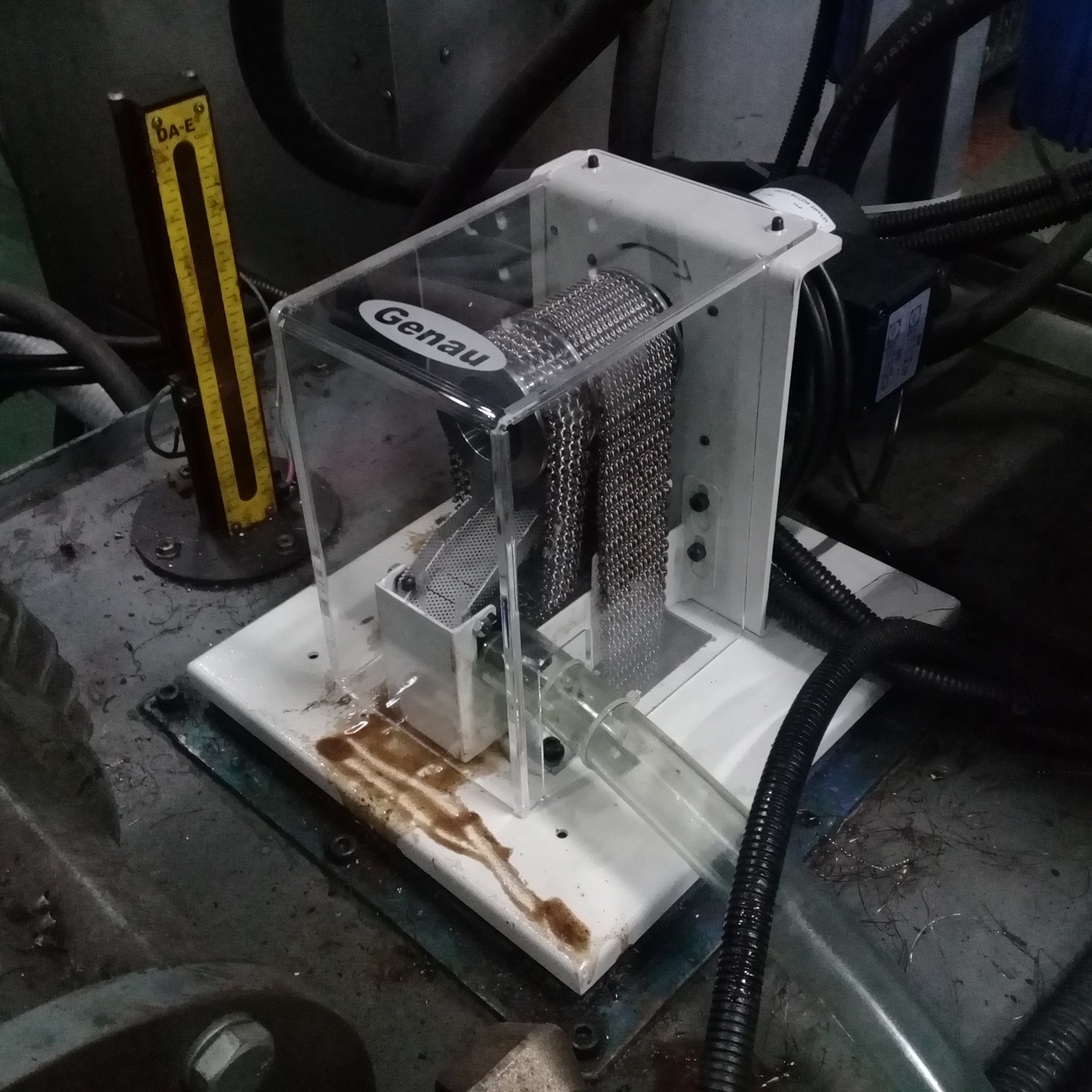

The condition improved greatly after Genau oil skimmer installed.

Click to see movie

Click to see movie

Click to see movie

Click to see movie

Click to see movie

Click to see movie

Before our skimmer was installed, the pump of the central filter tank must be replaced once a month for damage. The pump had large noise, low flow volume and vibration monthly after renewed. The surface of coolant had very thick tramp oil floating on above without skimmer.

For improving this situation, the floating vacuum sucker skimmer was adopted. But the very dirty and sticky tramp oil made the vacuum system failed quickly about 5 minutes and then worker spent 15 minutes to clean pipe, valve and chamber etc. Then the same process repeated again for the pipe blocked by this dirty tramp oil. The chief wished a solution to solve this trouble.

Our multi-step oil skimmer can carry out not only the tramp oil, the silt or mud attached with oil can also be removed smoothly. You can see the different versions of our front plate channels on improvement. When there was still a lot mud contained, the big hole on front plate channel can be open to remove mud. After a period of using, the cutting coolant becomes clean and the pump do NOT need to replace so frequently. The life of pump is extended due to our multi-step skimmer.

原本未配置油水分離機的中央過濾系統, 於加裝我司油水機後, 排出大量淤泥及廢油, 大幅改善切削液品質.

skip to main |

skip to sidebar

18-23 September

Booth: H6, L37

New Oil Skimmer

Period:17-22 Nov. 2016

Booth: E7060

Advanced Index Tables.

Oil Skimmer, Rotary Table, Index, Cast Iron, CNC Machines. オイルスキマー、円テーブル、割出盤、鋳物、工作機械

Genau International Co., Ltd.

- Home

- Profile会社紹介

- Products製品

- Download資料卸し

- Technique技術

- Application応用

- Skimmer case 1 Tooling Work Shop

- Skimmer case 2 Automobile Parts Maker

- Skimmer case 3 Small Lathe Shop

- Skimmer case 4 Mold and Tooling Work Shop

- Skimmer case 5 Mold Shop with Large Machining Centers

- Skimmer case 6 Lathe Work Shop for Mass Production

- Skimmer case 7 Automobile Gear Maker

- Skimmer case 8 Automobile Parts Heat Treatment

- Skimmer case 9 Cast Tooling Factory

- Skimmer Case 10 Hydraulic Housing Manufacture

- Skimmer case 11 Hardware Manufacture

- Skimmer case 12 Manual Chip-silt Collector SK-3

- Skimmer case 13 Central Filter System

- Skimmer case 14 Big Cast Tooling Factory

- Skimmer case 15 Automatic Exhaustor System SK-4

- Skimmer case 16 Very Sticky Status on Air Pump System

- Skimmer case 17 Extrement Sticky Tramp Oil SK-5

- Contacts連絡

Genau QR code

Business

Oil Skimmer

オイルスキマー

Rotary Tables

円テーブル

Cast Iron

鋳物生産

Accessories

付属品

Other Devices

周辺機器

Rotary Tables

円テーブル

Cast Iron

鋳物生産

Accessories

付属品

Other Devices

周辺機器

CNC Machines

CNC工作機械

V17MAY. 技術提供:Blogger.

Knowledge 知識

Application of rotary table

The basic usage of rotary table in machining center is to set up with a jig for multi-stage tooling on works. With the delicated design of j...

Popular 人気商品

Connect to Detail

New Oil Skimmer Movie

Show 展覧会

EMO 2017 Hannover

18-23 September

Booth: H6, L37

New Oil Skimmer

JIMTOF 2016 Tokyo

Period:17-22 Nov. 2016

Booth: E7060

Advanced Index Tables.

CTMS 2016 Taichung

Period: 20-24 May, 2016

Location: Chao-Ma Messe

Visit and Booth Survey

Latest News 会社動き

2017 May: New model of oil skimmer is developed. Marketing activity has kicked out. 新型のオイルスキマーは開発完成しました。今月から販売活動が始まります。

2017 March: Korean customer came Taiwan to confirmed new machine. The inspection was excellent and would be shipped soon. 韓国の客様は台湾で立会いを行い、新機械を確認し、直ぐ出荷を予定しました。

2016 Aug: President Mr. Nakashoji audited factories with good comments 中小路社長は工場を視察して、いい評判を出しました。

2017 March: Korean customer came Taiwan to confirmed new machine. The inspection was excellent and would be shipped soon. 韓国の客様は台湾で立会いを行い、新機械を確認し、直ぐ出荷を予定しました。

2016 Aug: President Mr. Nakashoji audited factories with good comments 中小路社長は工場を視察して、いい評判を出しました。

Cooperation 協力活動

2017 Feb: Korean Agent visited Genau and studied the strategy on cooperation for Korean customers. 韓国代理店が当社を来訪しまして、韓国の大手会社に向く戦略を検討しました。

2016 July: New product development with National Chin-Yu University of Technology 台湾の勤益科技大學と新製品開発の提携が始まりました。

2016 March: Strategic meeting with Dr. Huang at Business Administration Department of Da-Yeh university. 台湾の大葉大學企管系黃教授と戦略会議を行いました。

2016 July: New product development with National Chin-Yu University of Technology 台湾の勤益科技大學と新製品開発の提携が始まりました。

2016 March: Strategic meeting with Dr. Huang at Business Administration Department of Da-Yeh university. 台湾の大葉大學企管系黃教授と戦略会議を行いました。

Copyright © 2016 適聖國際有限公司Genau |

Contact Window Tel:+886-920-873-711 | E-mail:exact.robert2015@gmail.com

Movie of Oil Skimmer Working

Movie of Oil Skimmer Working